AI-Driven Housing Pipelines. From Parametric Model to Industrial Production

Visualization: © Ulrich Buckenlei | Editorial concept image on AI-supported planning of energy-efficient residential buildings and their integration into industrial manufacturing and logistics processes. The illustration serves analytical classification and does not claim technical completeness.

Housing construction is undergoing a structural transformation. Artificial intelligence, parametric modeling, and real-time simulation are turning buildings into programmable systems. Walls, insulation, windows, and energy modules are no longer isolated components but rule-based elements within an integrated digital architecture.[1][2]

Instead of sequential planning, downstream energy checks, and later cost corrections, AI enables the simultaneous evaluation of structural logic, material parameters, lifecycle efficiency, and regulatory requirements already during configuration.[7][12]

This shift does not merely accelerate processes. It changes the logic of construction itself. When the digital model becomes the central reference, the bottleneck moves from physical coordination to the quality of model architecture, data structure, and algorithmic validation.[5]

From Construction Drawing to Parametric System Model

Traditional construction processes are based on plans, documents, and handovers between disciplines. Architecture, structural engineering, energy planning, and execution often follow a linear logic. Errors or optimization potential frequently become visible only in later phases, with corresponding cost implications.[3]

With the introduction of AI-supported planning tools, this structure changes fundamentally. The building is modeled as a structured dataset. Every wall contains material definitions, U-values, and load-bearing parameters. Windows are not just openings but thermally and regulatorily evaluated modules. Energy systems are integrated as performance datasets.[6][11]

The decisive difference lies in simultaneity. Heat flow, carbon footprint, cost, and construction time can be simulated and adjusted in real time. Optimization thus becomes not a downstream correction but an integral part of the design phase.[7]

The key insight: planning becomes a validated system process rather than a sequence of isolated documents.

- Planning logic shifts from document-based to data-based

- Energy and sustainability metrics are integral components of the model

- Regulatory requirements can be algorithmically checked at an early stage

- Error costs shift from the construction site to digital validation

Parametric housing planning with integrated real-time energy and carbon analysis

Visualization: © Ulrich Buckenlei | Editorial concept image of an AI-supported planning environment in which building components are configured and energy metrics are evaluated instantly. The illustration is schematic.

The visualization illustrates this shift. A parametric building model is configured while energy efficiency, material selection, and cost indicators are displayed in parallel. Interaction no longer takes place solely through drawings but through validated parameters.

The previous section described the structural shift. The following section analyzes under which conditions this integrated model architecture is also economically superior.

Economics of the Digital Construction Pipeline. When AI-Supported Planning Becomes More Cost-Efficient

The debate on AI in construction often focuses on automation. Economically decisive, however, is the system architecture. Not individual simulations create cost advantages, but the seamless connection of planning, energy analysis, bill of materials, and production data.[1][4]

Digital systems also generate costs: data preparation, model maintenance, interface integration, computing power, and quality assurance. The key transformation therefore lies not in cost elimination but in cost structure.[6]

While traditional construction processes generate high fixed costs through planning disruptions and on-site corrections, an AI-driven pipeline shifts these risks into early simulation and validation. The more variant generation, customization, and serial production are combined, the greater the potential economic advantage.[11][15]

- End-to-end data models reduce coordination costs

- Energy and carbon evaluation takes place during configuration

- Automated bills of materials reduce manual coordination

- Digital approvals shorten decision cycles

End-to-end construction pipeline. From model configuration through simulation and production approval to assembly

Visualization: © Ulrich Buckenlei | Editorial concept image of an integrated construction pipeline including data export, manufacturing, and logistics. The illustration serves systemic visualization.

The graphic makes clear that value creation is not shortened but redistributed. Model quality, data integrity, and interface expertise become strategic factors.

The following section analyzes how this cost migration affects market structure, platform logic, and strategic control.

Strategic Repositioning. Who Controls the AI-Driven Construction Architecture?

With the integration of planning, simulation, and production, efficiency is not the only outcome. A new power architecture emerges. Whoever defines model standards, interfaces, and data flows controls essential parts of value creation.[5][9]

The building becomes a digital asset. Digital twins, BIM data, and AI models generate long-term informational value regarding operation, maintenance, and sustainability.[2][7]

This shifts strategic positioning. Construction companies evolve into system integrators. Software providers become infrastructure operators. Platforms influence regulatory integration and data standards.[3][12]

- Data ecosystems replace isolated project logic

- Digital twins become strategic long-term assets

- Platforms shape standards and interfaces

- Competition emerges through architectural control

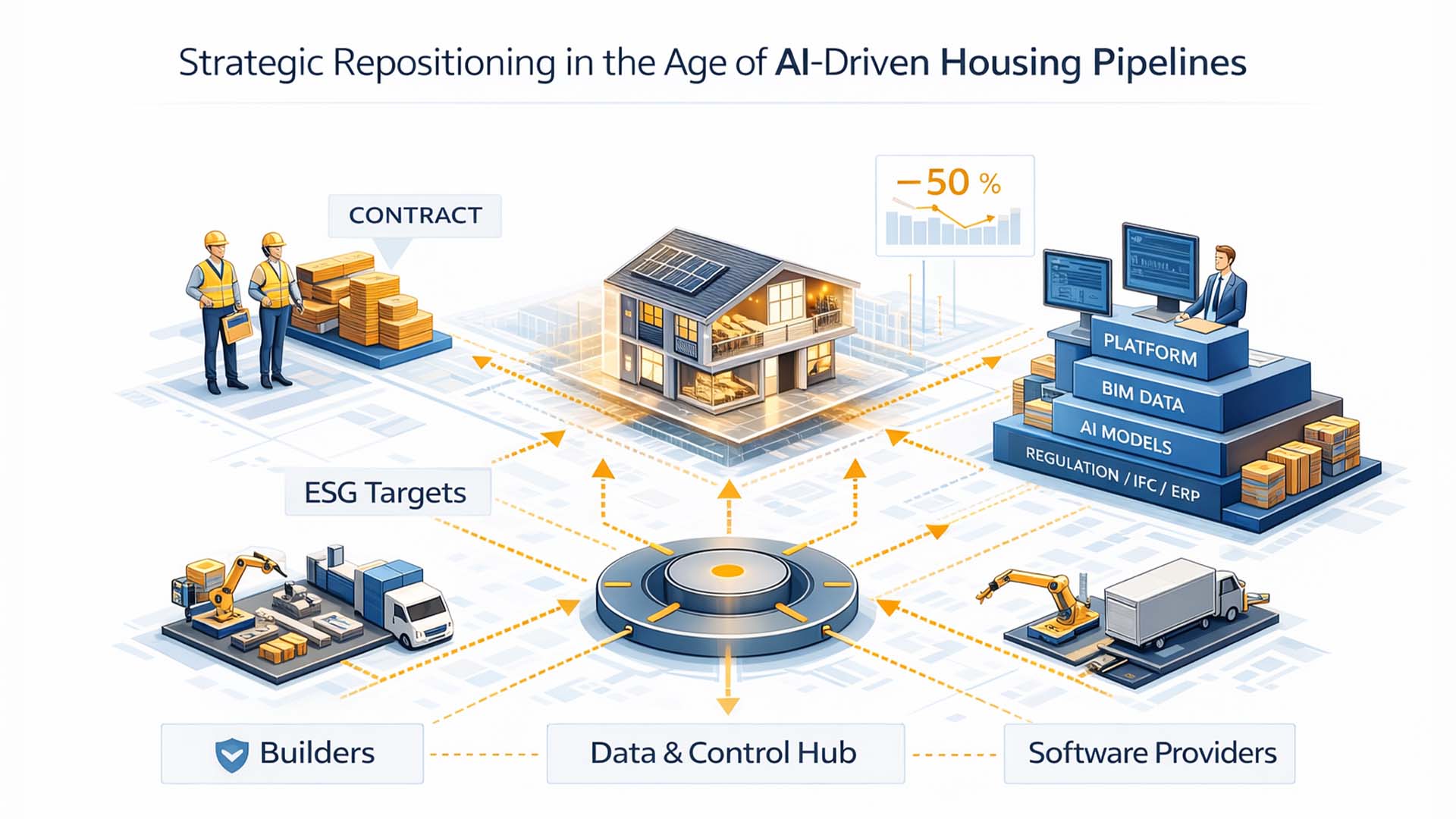

Strategic ecosystem. Construction firms, platforms, and AI models connected through a central data and control hub

Visualization: © Ulrich Buckenlei | Editorial infographic on the strategic shift in AI-driven housing. The illustration is schematic and serves analytical classification.

The visualization shows the new ecosystem. At its center stands the digital building model as a data and control hub. From there, connections extend to construction execution, platform architecture, ESG targets, and production systems.

The following section examines the role of sustainability metrics, lifecycle optimization, and regulatory integration in the long-term transformation of housing construction.

From Planning to Impact in the Real District

So far, it has become clear how planning, cost structures, and strategic positioning change through AI-supported model architectures. Decisive, however, is not the tool itself but the measurable impact in the built environment. Only when digital models lead to realized districts that are demonstrably more energy-efficient, resource-conscious, and economically resilient does the pipeline architecture unfold its full potential.[2]

AI-based planning and simulation systems make it possible to systematically optimize energy metrics even before construction begins. Daylight ratios, solar yields, material selection, thermal insulation, and building technology are no longer considered in isolation but evaluated within an integrated model. Sustainability thus shifts from an additive goal to an algorithmically controlled core parameter.[6]

- Energy performance becomes quantifiable in the design phase

- Carbon reduction becomes a controllable planning parameter

- BIM data, ESG targets, and operational simulation merge into one system

- Long-term lifecycle optimization replaces short-term individual decisions

AI-supported residential district with measurable energy and carbon performance in operation

Visualization: © Ulrich Buckenlei | XR Stager NewsRoom | Editorial concept image illustrating an AI-supported residential district with indicators for carbon emission reduction, energy autonomy, smart grid integration, lifecycle efficiency, and predictive maintenance. The image serves analytical classification and presents a conceptual, non-project-specific depiction.

The visualization highlights the final stage of the pipeline. The building is no longer just an object but part of a connected system. Energy flows, carbon reduction, smart grid integration, and predictive maintenance are integral components of the digital twin. AI operates not only in the background of a planning tool but within the ongoing operation of the district.[8]

The scalability of this approach is particularly relevant. When planning data, construction execution, and operational data are connected via standardized interfaces, a continuous optimization cycle emerges. Each realized project improves the models of the next. Sustainable housing thus becomes not only more efficient but adaptive and learning.[14]

The real transformation therefore lies less in the individual building than in the systemic context. AI enables housing to be planned not only faster or more cost-effectively but to be operated in a more energy- and resource-resilient manner over the long term. In times of increasing regulatory requirements and expanding ESG reporting obligations, this integrated perspective becomes a decisive competitive factor.[13]

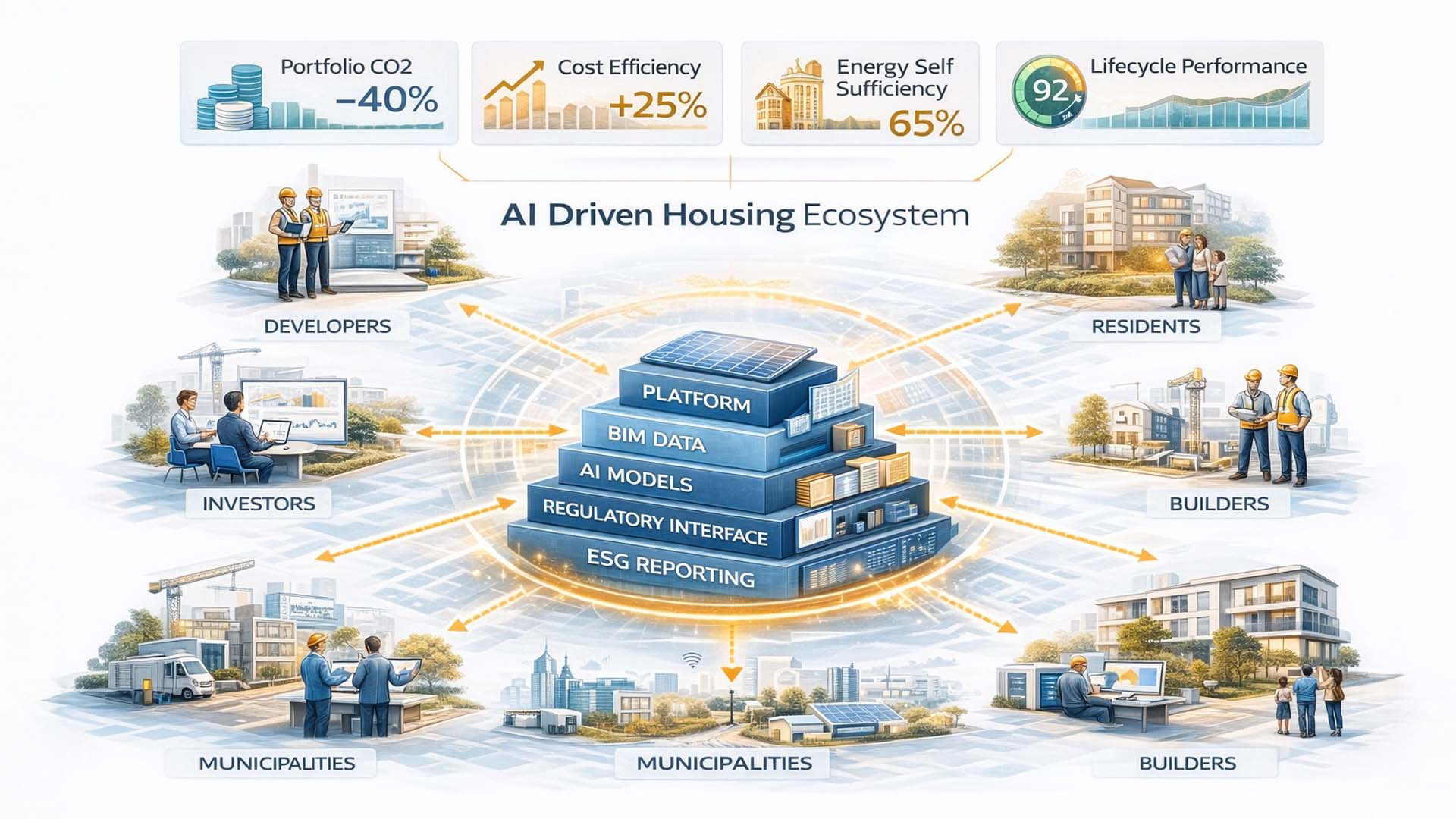

Scaling Toward a Data-Driven Housing Ecosystem

After demonstrating how AI-supported planning makes real districts more energy-efficient and sustainable, the next strategic question arises: What happens when this model no longer applies to individual projects but to entire portfolios, cities, or developer structures? The true disruption does not occur at the level of a single building but in systemic scaling.[3]

AI unfolds its full impact where planning data, construction processes, regulatory requirements, and operational data are connected through a central platform. Individual projects evolve into an integrated housing ecosystem. BIM data, ESG reporting, regulatory interfaces, and AI models interlock to create a continuously learning infrastructure.[11]

- Planning, construction, and operation merge into a continuous data chain

- Portfolio performance becomes measurable and comparable

- ESG metrics are generated automatically from real-time data

- Scaling increases not only efficiency but system intelligence

AI-supported housing ecosystem with central platform architecture and connected stakeholders

Visualization: © Ulrich Buckenlei | XR Stager NewsRoom | Editorial system image illustrating a data-driven housing ecosystem with platform core, BIM data, AI models, regulatory interface, and ESG reporting. The graphic serves analytical classification and presents a conceptual architecture without claiming project-specific completeness.

The graphic makes visible what becomes strategically decisive. At the center is no longer the building but the platform. From it, data streams extend to developers, investors, municipalities, construction firms, and residents. Value creation emerges through coordination and transparency. Whoever controls the platform controls the information architecture of housing construction.[12]

For investors, this means a new quality of decision-making. Portfolio carbon reduction, cost development, energy autonomy, and lifecycle performance are no longer measured retrospectively but continuously monitored. Sustainability thus shifts from a marketing promise to an operational control variable.[15]

At the regulatory level, this integration gains further relevance. With expanding reporting obligations and ESG requirements, the ability to structure and automatically evaluate data becomes a competitive factor. AI acts as the link between planning, compliance, and operation.[13]

The following chapter examines the long-term implications of this platformization for market structure, ownership models, and the role of traditional construction stakeholders.

New Decision Architectures in AI-Supported Housing Construction

With the transition to a data-driven housing ecosystem, not only technology changes but also responsibility. AI systems deliver scenarios, forecasts, and optimization proposals in real time. Strategic decisions, however, remain human. The real transformation therefore lies in the reorganization of decision processes.[12]

Where static reports, isolated spreadsheet models, and fragmented data sources once dominated, integrated simulation environments now emerge. Scenario analyses on energy consumption, carbon development, investment risks, and regulatory compliance can be calculated in parallel and visually compared. Planning becomes more transparent but also more complex.[11]

- Scenario simulation replaces linear forecasting models

- Energy and carbon metrics become core decision parameters

- Regulatory compliance is integrated at an early stage

- Investment risks can be assessed on a data-driven basis

Strategic decision session with AI-supported scenario simulation and digital twin visualization of a residential district

Visualization: © Ulrich Buckenlei | XR Stager NewsRoom | Editorial concept image illustrating a strategic decision architecture in AI-supported housing. Shown is an interactive scenario simulation with energy impact comparison, carbon forecast, investment risk analysis, and regulatory compliance status. The image serves analytical classification.

The visualization illustrates how governance in housing construction is shifting. Architects, project developers, investors, and construction managers no longer operate based on isolated documents but within a shared data space. The digital twin becomes the foundation for discussion. Decisions emerge from comparable scenarios rather than assumptions.[8]

At the same time, responsibility increases. The more deeply AI models intervene in planning and operation, the more important transparency, traceability, and model governance become. Who defines the optimization goals? Which parameters receive priority? Which ESG targets are binding? These questions determine the real-world impact of the technology.[13]

In the long term, not only production logic shifts but also the distribution of power within the system. Actors who understand data, interpret scenarios, and evaluate them strategically gain influence. AI becomes an amplifier of human decision competence, not its replacement.

In the concluding chapter, these structural changes are synthesized into a strategic perspective for developers, investors, and cities.

Video Analysis – From Configuration to Production-Ready Digital Twin

The following video demonstrates how AI-supported planning not only visualizes designs but integrates structural, energetic, and economic parameters in real time. At its core is a platform architecture that treats buildings as parametric data systems rather than static geometry.[3][11]

Walls contain material logic and load assumptions. Windows and doors include thermal performance values and regulatory requirements. Energy systems are linked with performance and efficiency data. As configuration is adjusted, AI simultaneously evaluates structural stability, energy behavior, and cost implications. Planning, validation, and optimization merge into a continuous process.[2]

Decisive is the integration into the production chain. The resulting digital twin is not merely a visualization model but a manufacturing-ready data system. It connects directly with automated factory processes and enables configurable housing units that can be specified, validated, and ordered within the same platform.[15]

A seamless pipeline emerges: design, simulation, regulatory validation, cost calculation, and industrial production operate as one coherent system. At this interface, scalability, efficiency gains, and structural cost advantages arise.

AI-supported housing platform with parametric configuration and production-ready digital twin

Industrial housing platform: ZURU Tech | AI-driven configuration platform: DreamCatcher |

Speaker analysis and commentary: © Ulrich Buckenlei

The example illustrates the transition from a sequential construction process to an integrated, data-driven production logic. It is not individual steps that are optimized, but the entire value chain that is synchronized.

In the final section, this leads to a strategic perspective for developers, investors, and cities.

Sources and References

- Şenel Solmaz, A., “From Blueprint to Reality: Digital Twins in Architecture, Engineering and Construction”, Journal of Innovative Engineering and Natural Science, 2025. [1]

- Zhang, Z. et al., “Digital Twin Technologies for Enhanced Sustainability in Construction”, Buildings, 2024. [2]

- Cespedes-Cubides, A. S. & Jradi, M., “Building Digital Twins to Improve Energy Efficiency”, Energy Informatics, 2024. [3]

- Alnaser, A. A. et al., “AI-Powered Digital Twins and IoT for Smart Cities and Sustainable Building Environment”, Applied Sciences, 2024. [4]

- Bibri, S. E. & Huang, J., “AI and AI-Powered Digital Twins for Zero-Energy Buildings”, Environmental Science & Ecotechnology, 2025. [5]

- Morkunaite, L. et al., “Digital Twin Modeling of Residential Building Thermal Dynamics”, arXiv Preprint, 2024. [6]

- Amarkhil, Q. et al., “AI-Driven Semantic Framework for Automated Construction Planning”, Engineering Proceedings, 2025. [7]

- Mehr anfar, M., Braun, A., & Borrmann, A., “End-to-End AI Automation from Point Clouds to Semantic Building Models”, Automation in Construction, 2024. [8]

- Advanced Engineering Informatics, Special Issue: Artificial Intelligence for the Built World, 2026. [9]

- Energy and Built Environment, “Digital Twin Technology for Thermal Comfort and Energy Efficiency”, 2024. [10]

- Filippova, E. et al., “Artificial Intelligence and Digital Twins for Bioclimatic Building Design”, Energies, 2025. [11]

- Li, Y., “AI-Enhanced Digital Twins for Energy Efficiency and Carbon Footprint Reduction”, Applied and Computational Engineering, 2025. [12]

- IEA EBC Programme, Annex on Data-Driven Smart Buildings, 2023–2025. [13]

- McKinsey & Company, “The Next Normal in Construction: How Disruption is Reshaping the World’s Largest Ecosystem”, 2024 Update. [14]

- World Economic Forum, “Digital Transformation of Construction and Infrastructure”, 2023–2024 Reports. [15]

- Grieves, M., “Digital Twin: Manufacturing Excellence through Virtual Factory Replication”, White Paper (Revised Edition), 2014/Updated Citations 2023. [16]

- Eastman, C., Teicholz, P., Sacks, R., & Liston, K., “BIM Handbook: A Guide to Building Information Modeling”, 3rd Edition, 2018 (Foundational Reference). [17]

- Kolarevic, B., “Architecture in the Digital Age: Design and Manufacturing”, Updated Academic Edition Referenced in Parametric Design Research, 2019. [18]

- Schwab, K., “The Fourth Industrial Revolution”, Updated Contextual Edition for Industry 4.0 Frameworks, 2017/Referenced 2023+. [19]

- ISO 19650, “Organization and Digitization of Information about Buildings and Civil Engineering Works – BIM”, Latest Revision, 2018 (Current Standard in Use 2023+). [20]

When Housing Construction Becomes Data-Driven, It Takes More Than a Planning Tool

AI-supported housing construction is not an isolated software topic but a structural transformation of the entire value chain. As soon as buildings are conceived as parametric data systems and planning, simulation, regulatory validation, and production converge into a continuous pipeline, responsibilities, decision logics, and business models change.

The central question is not whether AI can optimize floor plans or calculate energy metrics. What matters is how to build a resilient end-to-end architecture: from strategic goal definition through data structuring, model architecture, and simulation to manufacturing integration, ESG reporting, and operations. Anyone aiming to deliver scalable and sustainable housing needs an integrated platform logic, not isolated silo solutions.

This is exactly where the Visoric expert team in Munich operates. We support developers, investors, municipalities, and technology partners in strategically designing, technically evaluating, and operationally implementing AI-supported planning and production pipelines. Our focus is on system architecture, data integration, digital twin strategies, and sustainable scaling.

The Visoric Expert Team. Strategic consulting for AI-supported planning, digital twin architectures, and scalable housing pipeline systems

Source: VISORIC GmbH | Munich

- Strategic analysis → Evaluate use cases, ESG requirements, and scaling potential

- System architecture → Platform design, data modeling, and integration strategy

- Proof of concept → Simulation, performance benchmarking, and business case analysis

- Pipeline integration → Connect planning, manufacturing, and operations

- Digital twin strategy → Real-time monitoring, lifecycle optimization, and reporting

- Governance → Transparency, compliance, and sustainable decision architectures

If you want to explore how AI-supported housing pipelines can be implemented in your organization efficiently, in a regulatory-safe way, and at economic scale, a conversation with the Visoric expert team in Munich is worth it.

Contact Us:

Email: info@xrstager.com

Phone: +49 89 21552678

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobil +49 152 53532871

Mail: ulrich.buckenlei@xrstager.com

Nataliya Daniltseva (Projekt Manager)

Mobil + 49 176 72805705

Mail: nataliya.daniltseva@xrstager.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich