Industrial AI at SPS 2025 – How Siemens Automates the Automation Itself

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

From Programming to Orchestrating: Rainer Brehm on the Next Stage of Automation

At SPS 2025 in Nuremberg, Rainer Brehm, COO of the Automation Unit and CTO of Siemens Digital Industries, paints a clear picture of how the world of manufacturing will change. The key message of his presentation at the Siemens booth: We are at a turning point where it is no longer just machines that are being automated, but automation itself. Engineering, code, testing and optimization gradually move from manual workflows to AI-supported and, in the long term, agent-driven processes.

Brehm describes three levels on which Industrial AI is already working today. First, in products where AI is invisibly integrated and users are not even aware that they are working with intelligent algorithms. Second, in the form of copilots that actively support engineering teams by suggesting code, generating documentation and preparing test cases. And third, in systems where companies have built up so much experience that they can train highly specialized AI workloads on their own infrastructure and deploy them on the shop floor. From Siemens’ perspective, this is not a distant future scenario but a transformation that has already visibly begun.

- From expert tools to democratized AI use → AI becomes accessible for more engineering teams

- Copilots as the new standard → from code suggestions to automated documentation

- Long-term vision → AI agents that control entire workflows in automation

Industrial AI on Stage: Rainer Brehm outlines the future of automated automation at SPS 2025.

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

Brehm uses an AI radar map on the main stage to illustrate how deeply Siemens integrates intelligence into its entire automation portfolio. The interplay of experience, engineering tools and industrial data processing creates an infrastructure that brings AI into real production processes in a scalable and secure way.

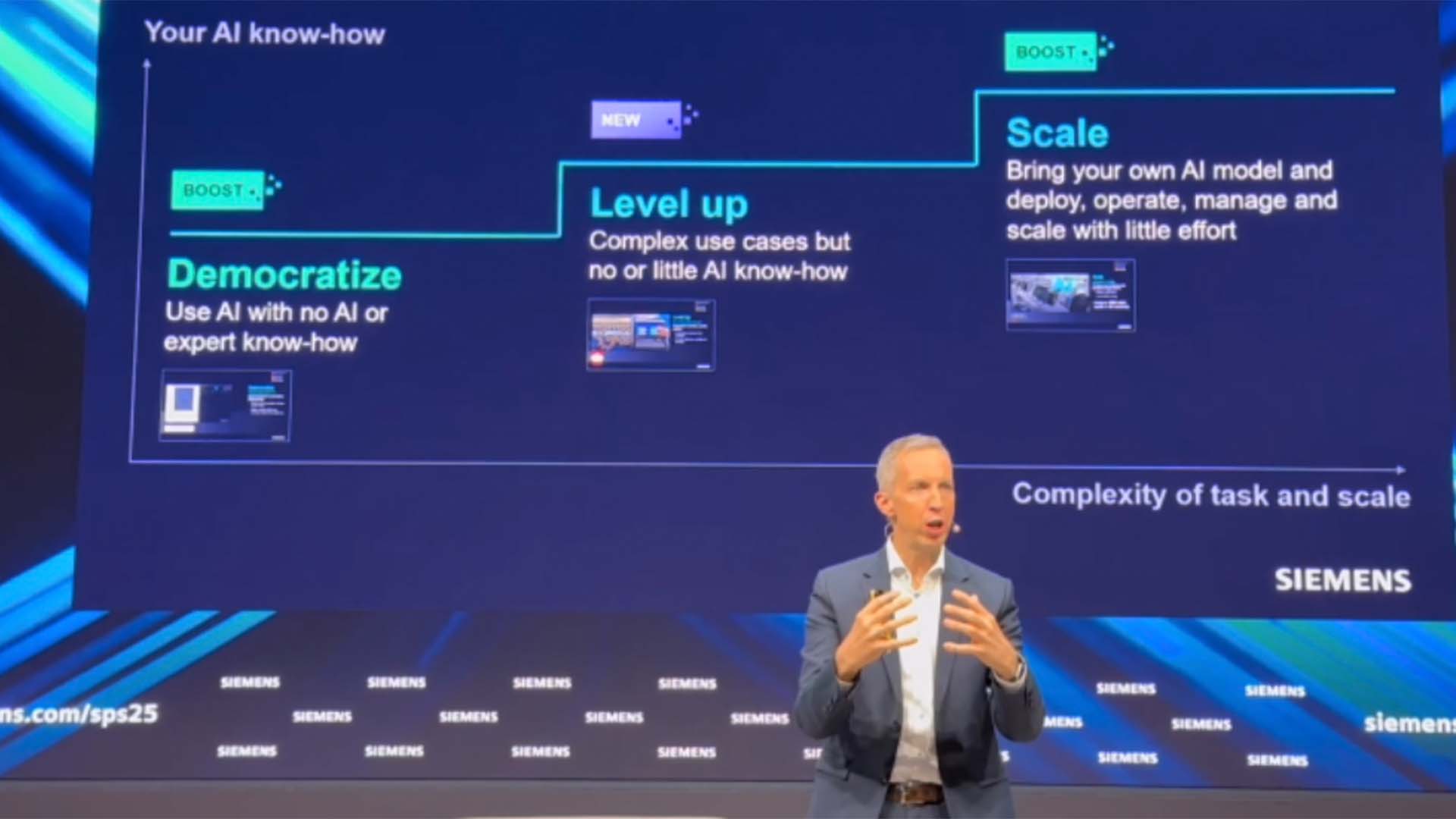

Three Levels of Industrial AI: From Easy Entry to Scalable In-house Model Ecosystems

The diagram shown clearly illustrates how Siemens structures access to Industrial AI. On the left, the journey begins with complete democratization: customers can use AI without having to build specific expertise or data science skills. Many use cases work “out of the box” – optimized parameters, intelligent suggestions or automated monitoring.

The second stage, Level Up, addresses more complex scenarios where little or limited AI knowledge is available. Here, tools and copilots help implement more demanding tasks such as code generation, test automation or HMI creation efficiently. The focus is on making teams productive quickly without overwhelming them with technical hurdles.

The third stage, Scale, is aimed at power users and experienced industrial customers who want to train, manage and deploy their own models at scale. This phase requires robust infrastructure, GPU-accelerated industrial edge systems and coordinated governance processes. It enables companies to develop customized AI workloads optimized for their specific plants.

- Democratize → use AI without building expert knowledge

- Level up → more demanding use cases supported by copilot technologies

- Scale → develop, deploy and operate your own models at large scale

Three levels of Industrial AI: From democratized use to scaling your own models.

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

During the presentation, Brehm explains how companies can grow step by step into the world of Industrial AI. The graphic clearly shows that Siemens not only offers individual AI functions but also a complete learning and growth architecture – from ready-to-use entry points to company-wide operation of proprietary AI models.

Why Siemens Leads in Industrial AI: Experience, System Competence and Data

The radar graphic shown by the ARC Advisory Group clearly places Siemens at the top of Industrial AI providers. The position stems from three factors: many years of experience in the automation environment, an end-to-end solution portfolio and the ability to integrate AI along entire value chains. Instead of isolated one-off solutions, Siemens relies on an interplay of products, systems and scalable Industrial AI services.

This becomes particularly clear against the backdrop of rising data volumes. By 2030, around 4.4 zettabytes of industrial data will be generated worldwide. Anyone who wants to make this data reliably usable needs not only AI but also robust platforms, edge integration, governance and a deep understanding of industrial processes. Siemens combines these requirements with decades of industrial practice – a central reason for its strong position on the radar.

- Leadership position according to ARC Advisory Group → combination of experience, portfolio and system competence

- 4.4 zettabytes of industrial data by 2030 → enormous potential for AI-driven production models

- End-to-end architecture → from automation hardware to AI-driven operations

Siemens in the Industrial AI ranking: Leading position in the ARC Advisory Group Champions Radar.

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

The image impressively shows how Siemens is evaluated in the category “AI-Driven Operations”: from product to system to solution level, the radar attests to an exceptionally high level of competence. For many visitors at SPS 2025, this was a visible indication that Industrial AI is not only a technical topic but is becoming a strategic differentiator in global manufacturing.

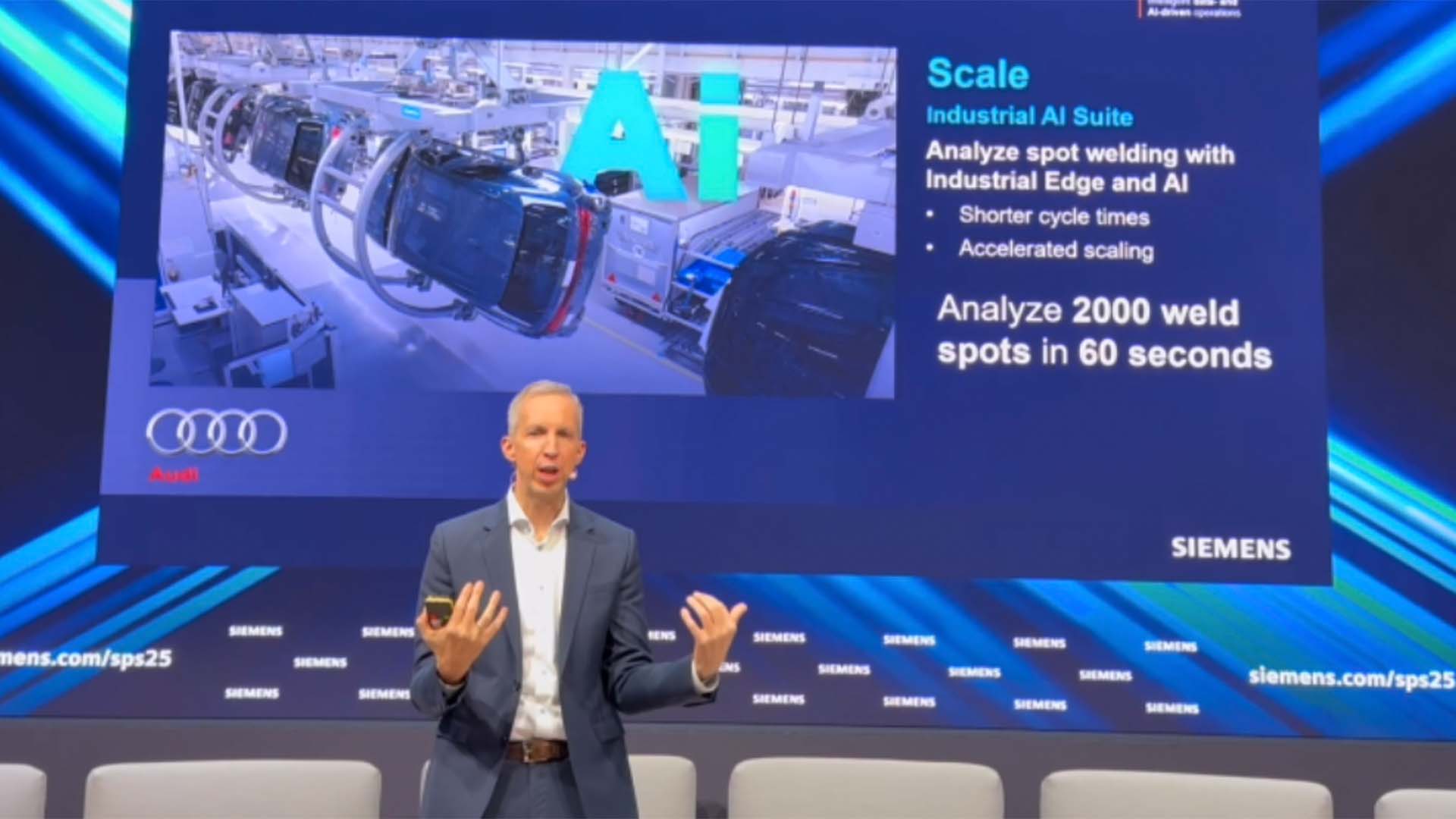

AI-supported Real-time Quality Control

The example shown illustrates how Industrial AI is already being used productively today. With the Visual Inspection Cockpit, Siemens demonstrates a solution that automates quality inspection directly on the running line. The image shows a bakery production line where AI models recognize shape, color and surface defects of individual products and classify them within milliseconds.

The key advantage lies in scalability. New product variants can be integrated into the system without extensive manual adjustments. The AI learns patterns, deviations and desired quality characteristics and quickly transfers this knowledge to new production series. For operators, this means more flexibility, less waste and a significant increase in process quality.

- Automated inline inspection → AI evaluates every product in real time

- Visual Inspection Cockpit → central overview of quality data and live analyses

- Rapid scalability → new product variants integrated without complex reprogramming

Level Up: Real-time quality control with the Visual Inspection Cockpit.

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

The scene shows the operator interacting with the system by touch, checking results and adjusting parameters. For many visitors at SPS 2025, this was one of the most practical examples of how Industrial AI not only accelerates manufacturing processes but also makes them measurably more robust.

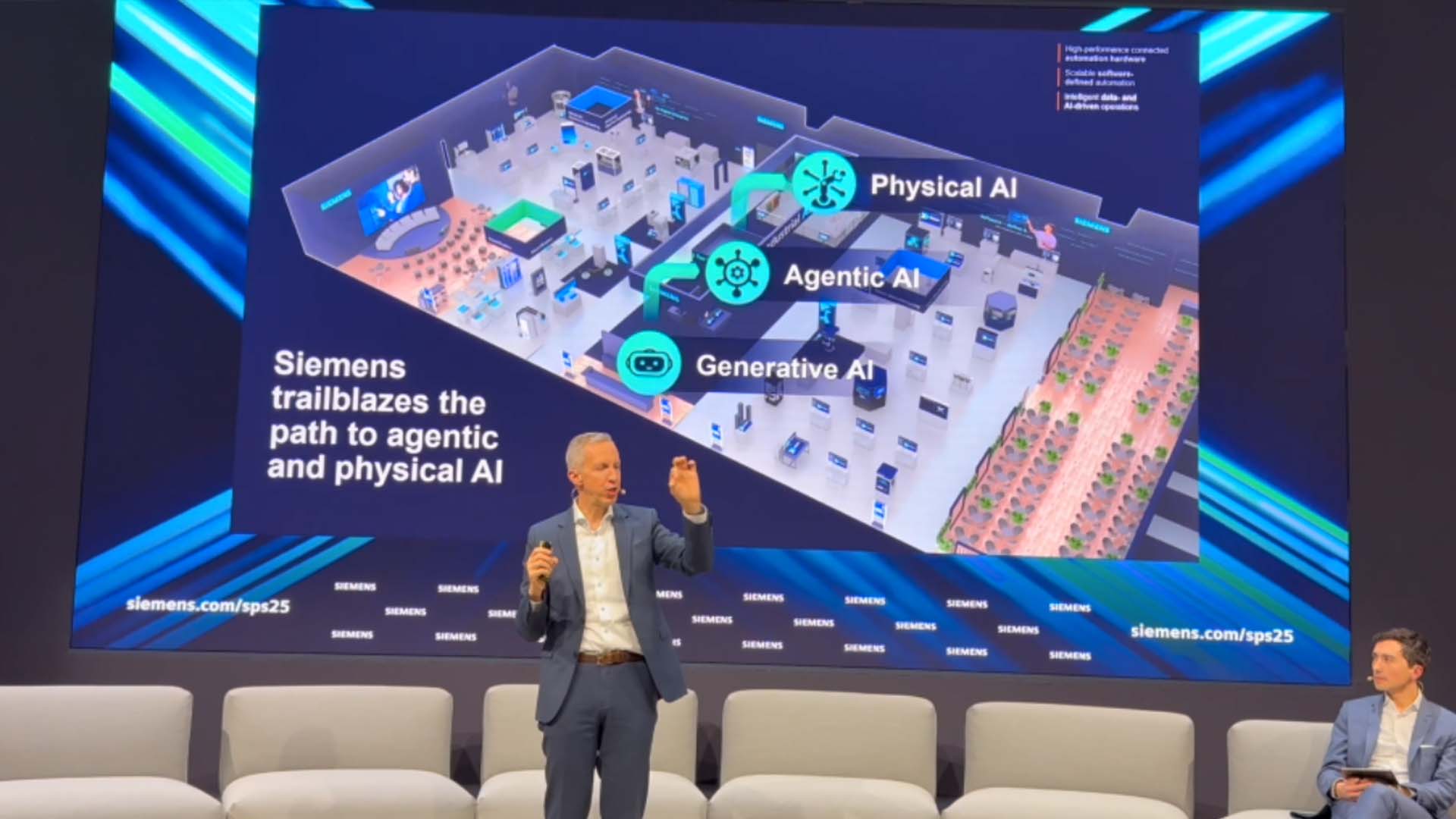

From Generative AI to Physical AI: The Path to Agentic Automation Systems

The image shows one of the central statements of the presentation. Siemens sees the future of automation in a multi-stage development path, ranging from generative AI models to agentic AI systems and ultimately to physical AI – AI that not only supports software processes but directly controls real plants, machines and production cells.

Generative AI forms the foundation. It helps teams write code, create documentation or prepare variants. The next stage is AI agents that take over entire workflows, prepare decisions independently and understand complex contexts in engineering. In the final stage, Physical AI emerges – systems that intervene directly in control, coordinate movements, evaluate quality or adapt processes. Siemens positions itself clearly as a driver of this development.

- Generative AI → supports engineering, documentation and variant creation

- Agentic AI → autonomous workflows and automated decision models

- Physical AI → AI controls real machines, plants and production units

The Siemens AI Path: From generative AI to agentic systems and on to Physical AI.

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

The visualization shows a complete factory environment in which the individual stages of AI evolution are already placed. For many visitors, it became clear here that AI will not be an add-on to automation but will become the infrastructure that orchestrates the entire manufacturing flow.

Automated Automation Along Digital Threads

The slide illustrates how Siemens understands the next evolution of automation: as an end-to-end connected data and process flow that links all engineering, production and operational phases. This digital thread is the basis for automation no longer consisting of isolated individual steps but functioning as a coherent, automatable system.

Three technical pillars are at the center: high-performance connected automation hardware, a scalable software-defined control layer and intelligent, data- and AI-driven operating models. When these layers interlock, an architecture emerges that continuously links machine design, commissioning and ongoing operation – paving the way for truly automated automation.

- High-performance automation hardware → reliably connected control and field systems

- Software-defined automation → flexible, scalable logic instead of rigid hardware boundaries

- AI-driven operations → data-based decisions and self-optimizing processes

Digital Thread Experience: Automation as a continuous data flow – from engineering to operations.

Photo: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

On stage, it becomes clear that Siemens does not view this digital thread as a vision but as an actively implemented architecture. Automation, engineering and operations are growing together and AI is becoming the connecting layer that accelerates and stabilizes this process.

Video: The Way We Automate – Impressions from the Siemens Booth

The following video shows the key excerpts from Rainer’s presentation. It documents the evolution from classic automation to AI-supported workflows, copilots, visual inspection and industrial foundation models.

Industrial AI on Stage: Rainer Brehm outlines the future of automated automation at SPS 2025.

Video: © Ulrich Buckenlei | XR Stager Magazine at SPS 2025 in Nuremberg

The sequence shows copilots, AI agents, virtual PLCs and edge vision systems in action. It summarizes how Siemens understands the future of automation: intelligent, connected and software-defined.

The Visoric Expert Team in Munich

The assessment of Siemens’ Industrial AI strategy is based on many years of experience in XR, AI, digital twins and the industrial metaverse. The Visoric team supports companies in visualizing complex technologies clearly and translating them into tangible solutions.

- Strategic consulting → Industrial AI, digital twins, industrial metaverse

- Design & visualization → real-time 3D, trade fair productions, data visualization

- Technical implementation → edge integration, AI pipelines, immersive spaces

The Visoric Expert Team: Ulrich Buckenlei & Nataliya Daniltseva

Source: Visoric GmbH | Munich 2025

If you want to implement industrial AI, virtual PLCs or automated engineering workflows, the Visoric team accompanies you from the initial idea to the final implementation – technology-oriented, visually sophisticated and strategically well-founded.

Contact Us:

Email: info@xrstager.com

Phone: +49 89 21552678

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobil +49 152 53532871

Mail: ulrich.buckenlei@xrstager.com

Nataliya Daniltseva (Projekt Manager)

Mobil + 49 176 72805705

Mail: nataliya.daniltseva@xrstager.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich