3D Scanning and AI – How Digital Capture Opens New Paths for Product Customization

Image: © Ulrich Buckenlei | Visoric 2025

From Physical Object to Digital Model: The New Standard of Product Customization

3D scanning and AI are transforming how products are developed, customized and manufactured. An object is captured with millimeter accuracy within seconds and converted into a digital model that can be edited, modified or extended immediately. This creates an efficient and flexible workflow that makes both custom single pieces and series adaptations significantly faster and more economical.

The technology establishes a new standard because it captures natural shapes with precision, derives variants automatically and transfers them into digital production processes. Where manual measurements, prototype building and long coordination phases were once required, a continuous digital pipeline now emerges. The result is better products, shorter development times and a level of flexibility in customization that has not been achievable before.

- Fast Capture → Products are digitized within seconds

- Automated Adaptation → AI generates variants and optimizations

- Seamless Processing → Digital models flow directly into design or production

From Object to Digital Twin: 3D scanning captures shapes and details with high precision.

Image: © Ulrich Buckenlei | Visoric 2025

The illustration shows how a physical product is captured by a modern 3D scanner. The surface is measured in real time while AI-based algorithms smooth, interpret and prepare the raw model for immediate use in the design process. This close integration of capture and intelligent processing forms the starting point for fully digital product customization in industry, manufacturing and custom production.

Digital Processing in Real Time: From Scan to Precise Model Analysis

As soon as the physical object is captured, the true strength of modern 3D scanning workflows begins. Scan data flows directly into specialized software that automatically interprets point clouds, meshes and surfaces. The user sees in real time how the digital model is created, cleaned and displays even the smallest details such as edges, radii or surface transitions with millimeter precision. This step forms the core of an intelligent and continuous digital process chain.

In the example shown, the user works on a laptop with the freshly scanned section of the rear fender. The software highlights different surface zones with color, detects geometry deviations and suggests optimizations. This combination of automated analysis and manual fine-tuning enables product adaptations to be implemented faster, more precisely and far more reproducibly than with traditional methods.

- Real-Time Visualization → Point clouds and meshes are processed instantly

- Intelligent Segmentation → AI automatically detects relevant geometry regions

- Precise Derivation → Digital models serve directly as a basis for adaptations

3D model of the scanned fender: The software prepares geometry, surfaces and segmentations in real time for further processing.

Image: © Ulrich Buckenlei | Visoric 2025

The new image shows the CAD-ready digital twin of the scanned rear fender. Colored surfaces mark different material or component zones, while AI-powered tools clean the mesh, fill holes and highlight areas for later customization. This automated analysis process significantly accelerates the transition from real geometry to digital manufacturing and design workflows.

From Digital Twin to Physical Component

Once the virtual model is ready, the step that often brings companies the greatest value begins: a real, installation-ready part is produced from the digitally adapted geometry. Additive manufacturing, CNC machining or hybrid processes use the digital model exactly where scanning and modeling ended. The result is not a generic standard part but a precisely fitting component tailored to the previously captured vehicle geometry.

In the example, an aerodynamic component is produced based on the scanned fender. The shape follows the real vehicle contour, and optimizations from the software – such as modified edges, reinforced areas or adapted airflow surfaces – have been incorporated directly into the printed part. This creates a component that not only visually fits into the vehicle but is also functionally tuned to its intended application.

- Direct Transition to Manufacturing → Digital models serve as templates for 3D printing and CNC

- Precision Fit → Components follow the scanned geometry with millimeter accuracy

- Fast Iterations → Variants can be tested, adjusted and reproduced quickly

From Data to Component: The technician inspects a 3D-printed spoiler element that matches the scanned vehicle geometry exactly.

Image: © Ulrich Buckenlei | Visoric 2025

The image shows the completion of the first process chain: the scanned vehicle in the background and the matched component in the technician’s hands. Through the combination of 3D scanning, digital model analysis and modern manufacturing, a continuous workflow emerges that no longer treats customization as a special case but as an integral part of product development.

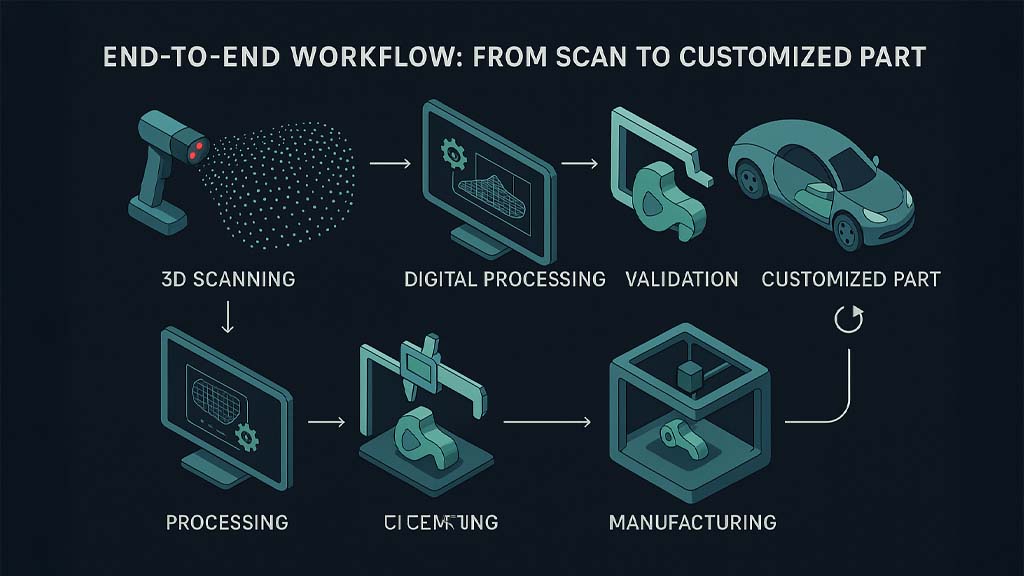

The Complete Workflow: From Reality to Digital Manufacturing

After presenting the individual steps of the workflow in detail, the following chapter shows the entire process chain in a single, clearly structured overview. Modern product customization today is based on a continuous digital workflow in which all phases – from scanning to analysis to production – interlock seamlessly. The result is an efficient, repeatable and highly precise process that provides companies with real time and quality advantages.

The infographic visualizes this end-to-end process at a glance. It shows how the real object is scanned, then imported as a point cloud and mesh into the software where it is further developed through AI-based analysis and optimization. The optimized dataset then serves as the basis for production – such as additive manufacturing or CNC machining – before the finished component is reinstalled or further processed on the real product. This closed process loop represents the core potential of modern digital product customization.

- Continuous Pipeline → Scanning, analysis, adaptation and production work seamlessly together

- High Process Reliability → Every step is digitally documented and repeatable

- Faster Product Development → Iterations are completed in hours instead of weeks

Infographic: End-to-end workflow from scanning and digital modeling to final production.

Graphic: © Ulrich Buckenlei | Visoric 2025

The illustration summarizes all steps visually: scanning with a 3D sensor on the left, digital processing of point clouds, meshes and AI optimization in the center, and the transition to manufacturing via 3D printing or CNC on the right. The dark, metallic color palette emphasizes the industrial character and blends harmoniously with the visual style of the article. The graphic provides a clear orientation and helps readers understand the full process chain from real geometry to finished component.

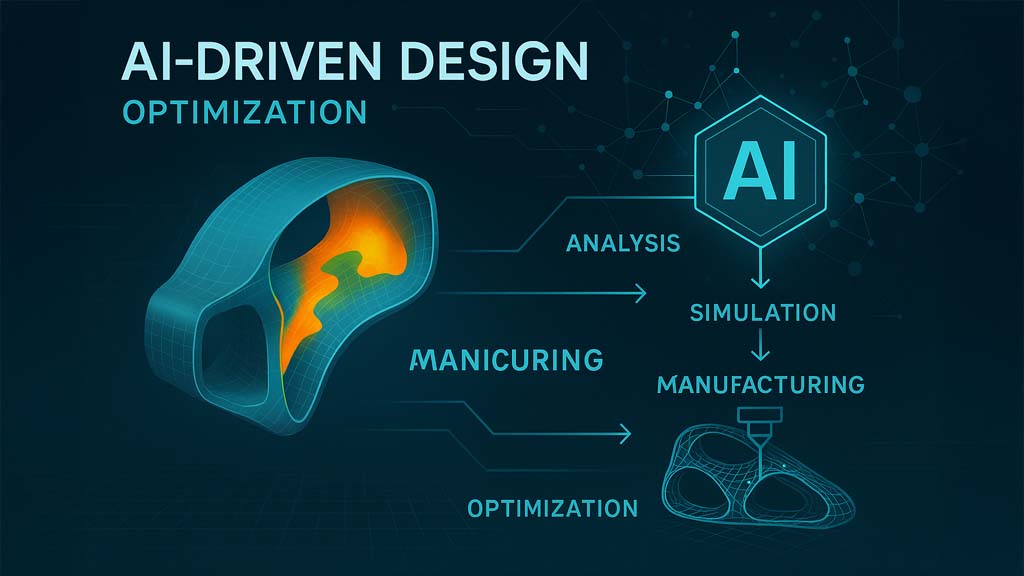

AI-Optimized Product Customization of the Future

The coming years will be shaped by an even closer fusion of 3D scanning, AI-driven model generation and automated production planning. Many technologies that today still exist as standalone tools will merge into fully integrated pipelines. This will create digital processes that are faster, more precise and more sustainable than anything previously possible.

- Artificial intelligence automatically analyzes scanned surfaces and detects material properties, damage or possible optimizations.

- Algorithmic assistants propose design variants in real time that are lighter, stronger or more aerodynamic.

- Digital twins simulate every modification before a physical part is even produced.

AI-Driven Workflow: Scanning, Analysis, Optimization and Production

Image: © Ulrich Buckenlei | Visoric 2025

The image shows a possible future version of a fully AI-powered product customization process. On the left is a digital twin generated from a high-precision 3D scan. An AI layer evaluates the scan data and highlights potential optimization areas in color. At the center of the image is a holographic interface that presents automatically generated variants. These variants account for structural stability, material consumption, aerodynamics and individual design preferences.

On the right side of the image is the automated production path: additive manufacturing, CNC optimization or hybrid processes are driven directly by AI-computed data. Every step is optimized for energy efficiency – machines adjust speed, material flow and tool motion autonomously to save resources.

This integrated workflow creates many measurable advantages. Component weight can be reduced, leading to lower fuel consumption or increased range in vehicles. Simulation-based precision eliminates much of the rework, reducing material waste and drastically lowering scrap rates. Workplace safety also increases because hazardous measuring, grinding or disassembly tasks move into the digital phase long before human intervention is required.

With AI-powered optimization loops, an entire production ecosystem emerges that is not only faster and more efficient but also significantly more sustainable. Products last longer, repairs become more predictable and resources are used more consciously. This future has already begun and is becoming increasingly visible with every step toward automation and intelligent manufacturing.

Video: The Entire Workflow in Motion

The following video shows the complete workflow of a modern 3D scanning process in the automotive sector. The footage documents how a real vehicle is captured segment by segment using a mobile handheld scanner. Reference points on the surface ensure maximum precision during reconstruction while the system continuously collects data and merges it into a detailed digital surface.

The speed at which the process proceeds is particularly impressive. The scan delivers results with virtually no delay and the generated data is ready for further digital processing immediately. Combined with downstream AI algorithms, the workflow becomes fluid, efficient and intuitive, offering significant advantages to both design teams and engineers.

3D Scanning Workflow in an Automotive Context

Video: Automotive workflow by Nikita Savvini and team | Commentary by Ulrich Buckenlei | Fair use for analytical purpose

The video shows how precisely the scanning markers are aligned on the vehicle surface and how the operator moves the sensor in calm, even motions. Each section of the body is captured step by step until a complete and seamless digital model is created. This method reduces sources of error, accelerates capture and provides a reliable basis for subsequent processing in design and manufacturing.

Such video documentation not only demonstrates technological progress but also illustrates the practical applicability of these processes in real production environments. The transition from physical capture to digital twin becomes tangible and shows how modern teams already rely on digital methods to shorten development times and increase quality.

The Visoric Expert Team in Munich

The workflows shown here do not arise by coincidence. Behind them is a team in Munich that has spent many years exploring how digital technologies can be used effectively to make development faster, more precise and more understandable. At Visoric, specialists from AI, 3D visualization, scanning, interaction and technical implementation work closely together with the goal of preparing complex technology in a way that provides real value in practical projects.

This interdisciplinary approach ensures that ideas are not only conceptualized but also supported all the way to their final application. Whether it is industrial prototypes, training systems, product design or immersive presentations, the team develops solutions that combine technological depth with clarity, accessibility and visual quality.

- Consulting & Concept → Strategies that align technical capabilities with practical needs

- Design & Content → Precise 3D visualizations, intuitive interactions and real-time simulations

- Technical Implementation → AI-powered workflows, motion intelligence and integrated XR systems

The Visoric Expert Team: Ulrich Buckenlei & Nataliya Daniltseva

Source: Visoric GmbH | Munich 2025

Ulrich Buckenlei and Nataliya Daniltseva represent the approach that defines Visoric: technology is not only used but truly understood and shaped. The goal is to apply digital tools in ways that support people, make ideas visible and demonstrably improve processes.

Many projects begin with a simple thought or an early sketch. From there, the team develops step by step a result that is technically solid and surprisingly intuitive at the same time. Anyone seeking to explore new paths – whether in product design, manufacturing, training or brand communication – will find people here who dive deep into challenges and develop solutions that genuinely move projects forward.

If you are considering building your own digital workflow or modernizing existing processes, the Visoric team is happy to define the next steps with you. Often, a first conversation is enough to reveal new opportunities and identify a direction that genuinely fits your project.

Contact Us:

Email: info@xrstager.com

Phone: +49 89 21552678

Contact Persons:

Ulrich Buckenlei (Creative Director)

Mobil +49 152 53532871

Mail: ulrich.buckenlei@xrstager.com

Nataliya Daniltseva (Projekt Manager)

Mobil + 49 176 72805705

Mail: nataliya.daniltseva@xrstager.com

Address:

VISORIC GmbH

Bayerstraße 13

D-80335 Munich